Fill out the form below to get started on your custom build!

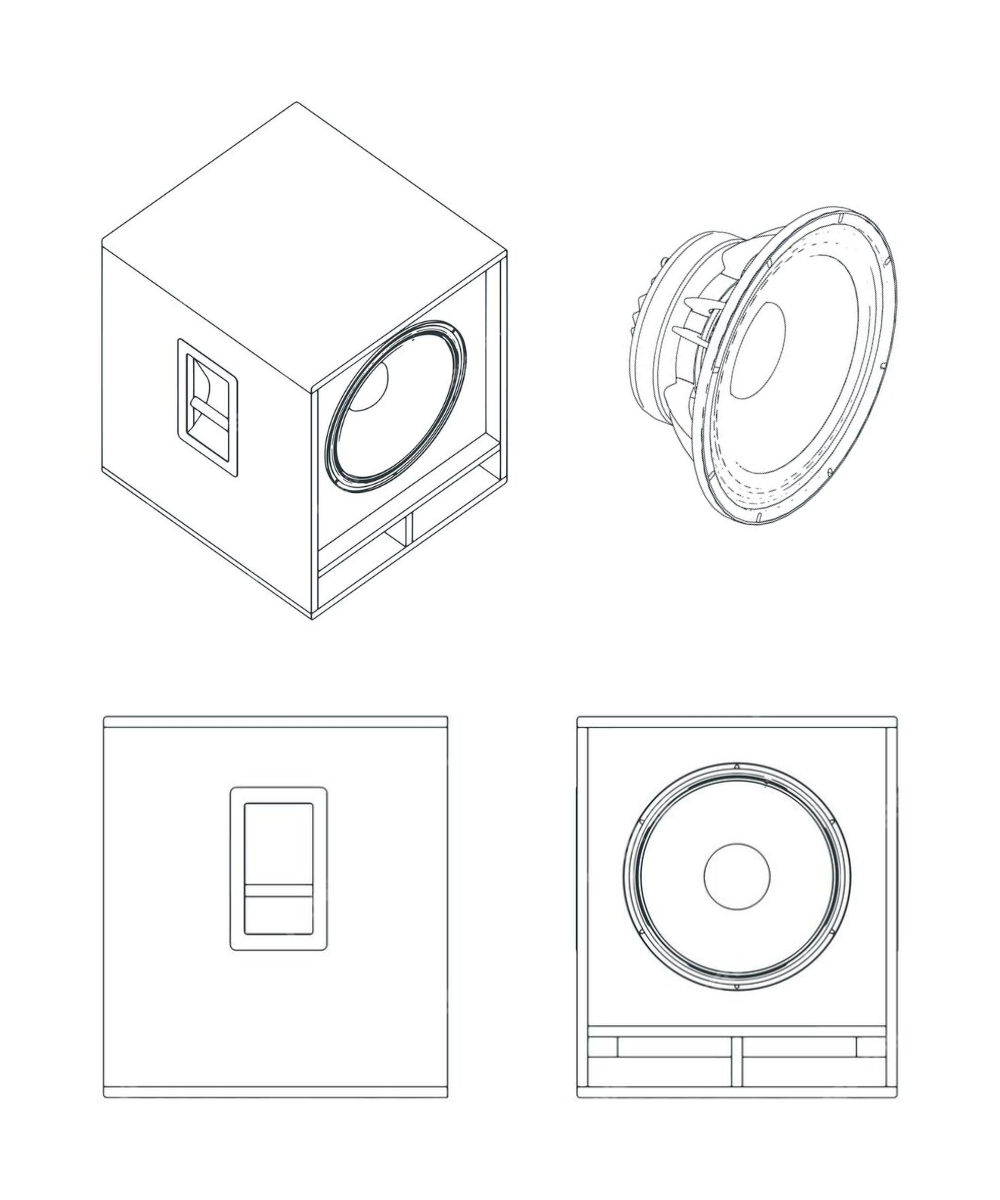

VAS Audio’s On-Demand Design & Build service offers complete loudspeaker development, from acoustic design and CAD modeling to prototyping and final production. Whether you’re a professional or a brand, our engineering team transforms your ideas into ready-to-build or fully assembled systems, optimized for performance, durability, and manufacturing efficiency.

Looking to build from scratch or optimize a prototype? We offer:

✔ Custom cabinet design & acoustic optimization

✔ Finalizing 3D files and converting to CNC-ready CAD

✔ System design consulting and measurement planning

✔ One-off prototypes or small series production

✔ Precise enclosure planning based on driver specs

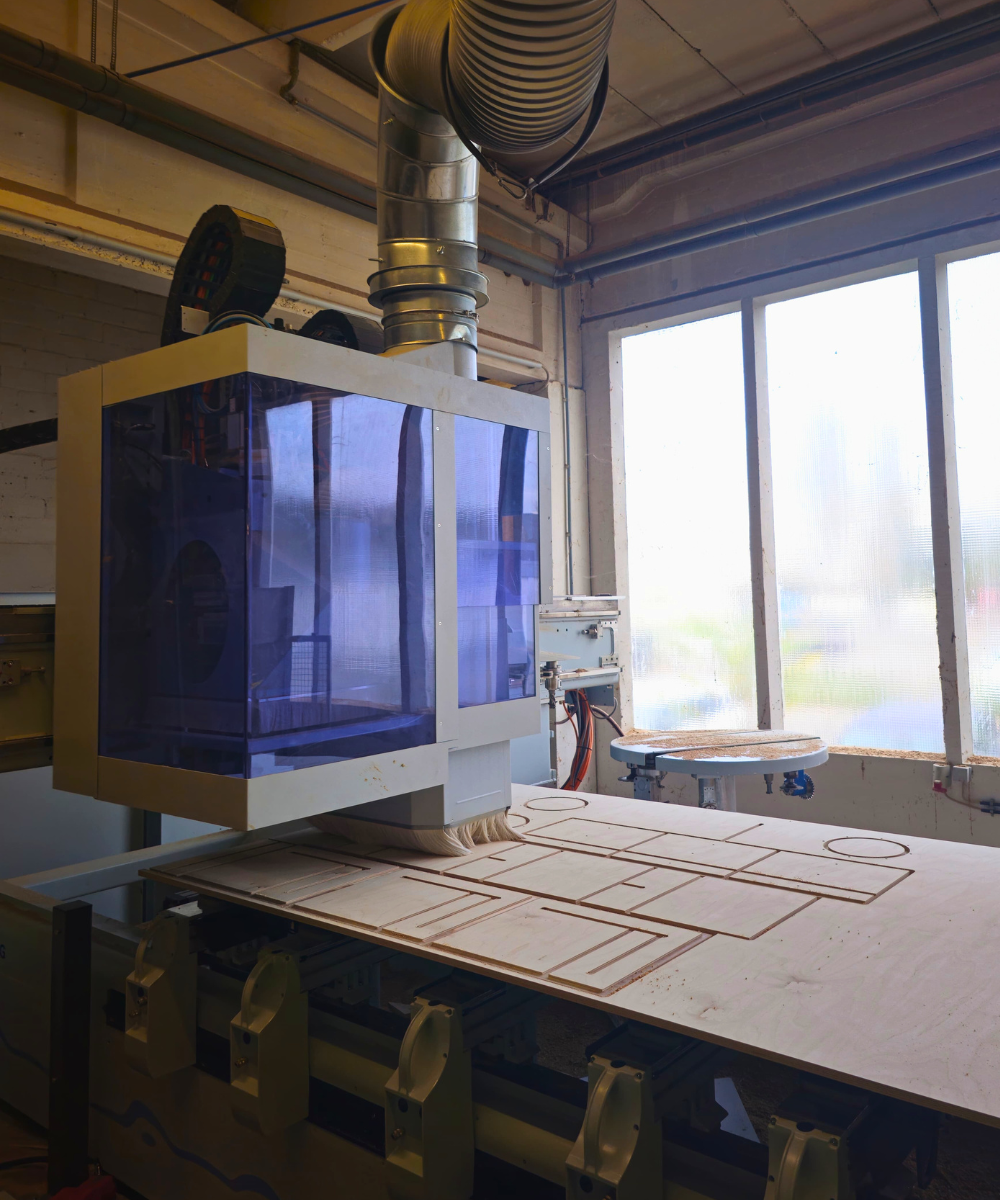

We don’t cut corners, unless it’s with our CNC machine.

✔ 15mm WISA-birch plywood (FSC™)

✔ Optional Polyurea Pro-coating

✔ Custom CNC logo engraving

✔ Rear panel & terminal modifications

✔ Handle, wheel plate & grille configurations

We bring it all together, so you don’t have to chase parts across the internet.

✔ System measurements

✔ Custom DSP tuning & preset creation for your setup

✔ Supply of transducers, DSPs, amps, and passive components

✔ Complete hardware sourcing: handles, terminals, grilles, screws, bolts, and more

✔ Established partner network to help source anything your system requires

FAQ

Can I build completely unique designs?

Yes! Our On-Demand Design & Build service allows you to bring your custom sound system vision to life. Whether you have a rough sketch, a concept in mind, or a detailed plan, we can design and build a system that matches your exact needs.

What if the design I have needs to be turned into CAD files?

If you have a 3D design or technical drawing, but it’s not yet in a format suitable for CNC machining, we offer CAD conversion services. We will transform your design into precise, optimized CAD files ready for manufacturing.

Our CAD-ing process includes:

✔ Finalizing the raw 3D file & converting it into CAD files for VAS CNC machining

✔ Panel cut-outs & rebates

✔ Precise screw bolt positioning

✔ Handle cut-outs & speakon cut-outs

✔ Driver cut-outs with precise bolt placements

✔ Wheel plate preparation with rear panel integration

Total estimated work time: 24 hours

What materials do you use for cabinet construction?

We use WISA-Birch Plywood with FSC™ certification (15mm of thickness) for its superior acoustic properties, durability, and CNC machining precision.

Want to partner with VAS Audio?

We offer OEM and B2B production, design services, and large-scale manufacturing solutions. Our in-house capabilities deliver precision, reliability, and a finish worthy of the world’s leading audio systems.